Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Binder Resin Production Line

-

≥1/set

USD 180,000.00

1.Raw Materials for Binder Resins

The choice of raw materials depends on the desired properties of the final product (e.g., water resistance, flexibility, curing speed). Common raw materials include:

-

Petroleum-Derived Monomers/Prepolymers:

-

Formaldehyde: A key reactant for phenolic, urea, and melamine resins.

-

Urea: Used with formaldehyde to produce Urea-Formaldehyde (UF) Resins.

-

Melamine: Used with formaldehyde to produce Melamine-Formaldehyde (MF) or Melamine-Urea-Formaldehyde (MUF) Resins, offering improved water and heat resistance.

-

Phenol: Reacts with formaldehyde to produce durable and water-resistant Phenolic Resins.

-

Isocyanates (e.g., MDI, PMDI): Used to produce Polyurethane (PUR) Binders, known for their excellent adhesion and flexibility.

-

Epichlorohydrin and Bisphenol-A: The main components for producing Epoxy Resins, known for strong adhesion and chemical resistance.

-

Acrylic Monomers (e.g., Methyl Methacrylate, Butyl Acrylate): Used to form Acrylic Resins, valued for their clarity, UV resistance, and durability.

-

-

Bio-Based/Renewable Materials (Growing Segment):

-

Lignin: A natural polymer from wood pulping, used as a partial substitute for phenol in phenolic resins.

-

Tannins: Natural polyphenols extracted from bark, can be used in resin formulations.

-

Starch and Soy Protein: Can be modified for use as binders, often in applications with less stringent performance requirements.

-

-

Additives & Catalysts:

-

Catalysts: Acids (e.g., ammonium sulfate for UF resins) or bases (e.g., sodium hydroxide for PF resins) to control the reaction speed and pH.

-

Scavengers: Substances like urea added to formaldehyde-based resins to reduce free formaldehyde emission.

-

Plasticizers: Added to improve flexibility and reduce brittleness.

-

Fillers: Sometimes added to modify viscosity, cost, or other properties.

-

2.Production Steps for Thermosetting Binder Resins (e.g., UF, PF, MUF)

The production is typically a batch process conducted in a stainless steel reactor equipped with a agitator, heating/cooling jacket, and condenser.

1. Charging / Loading

The initial reactants are charged into the reactor in a specific sequence. For example, for a UF resin:

-

Formaldehyde solution (often as formalin) is loaded first.

-

The pH is adjusted.

-

Urea is added in multiple stages.

2. Polycondensation Reaction (Alkaline Stage)

-

The mixture is heated under alkaline conditions (e.g., pH 7.5-8.5).

-

This stage involves the methylolation reaction, where formaldehyde attaches to urea (or phenol) molecules, forming methylol groups.

3. Polycondensation Reaction (Acidic Stage)

-

The pH is lowered to acidic conditions (e.g., pH 4.5-5.5).

-

This triggers the condensation reaction, where methylol groups link together, releasing water and forming methylene ether bridges. This builds the molecular weight and viscosity of the resin.

4. Neutralization and Vacuum Dehydration

-

Once the desired viscosity or molecular weight is reached, the reaction is stopped by neutralizing the mixture back to a neutral or slightly alkaline pH.

-

Vacuum dehydration is often applied to remove the water formed during the reaction. This concentrates the resin to the desired solids content.

5. Cooling and Discharge

-

The resin is cooled to ambient temperature to prevent any further reaction.

-

Finally, the finished binder resin is discharged from the reactor into storage tanks.

6. Quality Control and Blending

-

The batch is tested for key properties like viscosity, solids content, pH, and gel time.

-

Additives (e.g., scavengers, catalysts) are often blended in at this stage to create the final product ready for application.

3.Note on Other Resins:

-

Polyurethane Binders: Are produced by reacting polyols with a large excess of isocyanates to create NCO-terminated prepolymers. The final curing happens when the binder is applied and reacts with moisture in the air or the substrate.

-

Epoxy Binders: Are typically produced as a base resin (epoxide component) and a separate hardener (amine or anhydride component). They are mixed just before application.

TGM Chemical Machine Co., Ltd is a group enterprise. We have brands like TGM, Pengchang and Tongpeng.

We are a leader in the field of chemical machine industry, with 18 years of industry experience.

We have professional R&D design team, strong technical support, skilled production team, reliable after sales service, flexible customized solutions,

to meet your various standards and non standard equipment procurement needs. We committed to providing the complete and professional chemical equipment solutions.

We integrate, design, development, production, sales and training together.

Our products scope: Disperser, Bead Mill, Basket Mill, Mixer, emulsifier, Mixing kettles, Reactor, Filling machine, Bag filter, Pumps, Zirconium Bead, 3 roll mill, and other accessories.

Our machines help you to make ideal products: paints, coatings, inks, pigments, dyes, thinner, hardener, emulsions, varnish, spin finish, putty, glues, adhesives, viscous pastes, concrete Admixtures,

PCVC solvent cement, liquid resins, sealants, silicone sealant, lithium battery, electronic slurry&paste, pulps, silicon dioxide, liquid rubber, pesticide, liquid fertilizer, disinfectant, liquid detergent, gel,

lotions, shampoo, body wash, liquid soap, hand sanitizer, liquid wash, nail polish, creams, and so on.

We could offer individual machine or full production lines for your plants.

5. What are advantages of your factory?

1) Our factory is a leader manufacture of Chemical machine With 18 years of Industry experience. We have a lot Technology Patents & Product Patents;

2) Our factory has Professional R&D Teams, High Technical Supports, Skilled Production Team, Reliable After Sales Service, Flexible Customized Solutions;

3) Our factory is the leader of this industry, named with high and new technology enterprise;

4) Our factory has plenty of industry experience, we could offer you the complete palnt planning.

6. Who are your factory's clients? Could you list some of them?

AKZONOBEL, JUNTON, PPG, NIPPON, DABAO, BURGER, MAYDOS, RAINBOW, HITECH COATING, CHINA PAINT, CHANGJIANG COATING, TOA, LYNWON PIGMENT,

PEONY INKS, TL INKS, ZR INKS, SAKATA INKS, KINGSWOO INKS, DIC INKS, ANLI, ACHILLES, REPOW GROUP, SHINETSU ADHESIVES, JUSHI, XINGLONG PESTICIDES...

7. What certificate your factory could offer?:

CE, BSC, CNEX, ISO, patents.

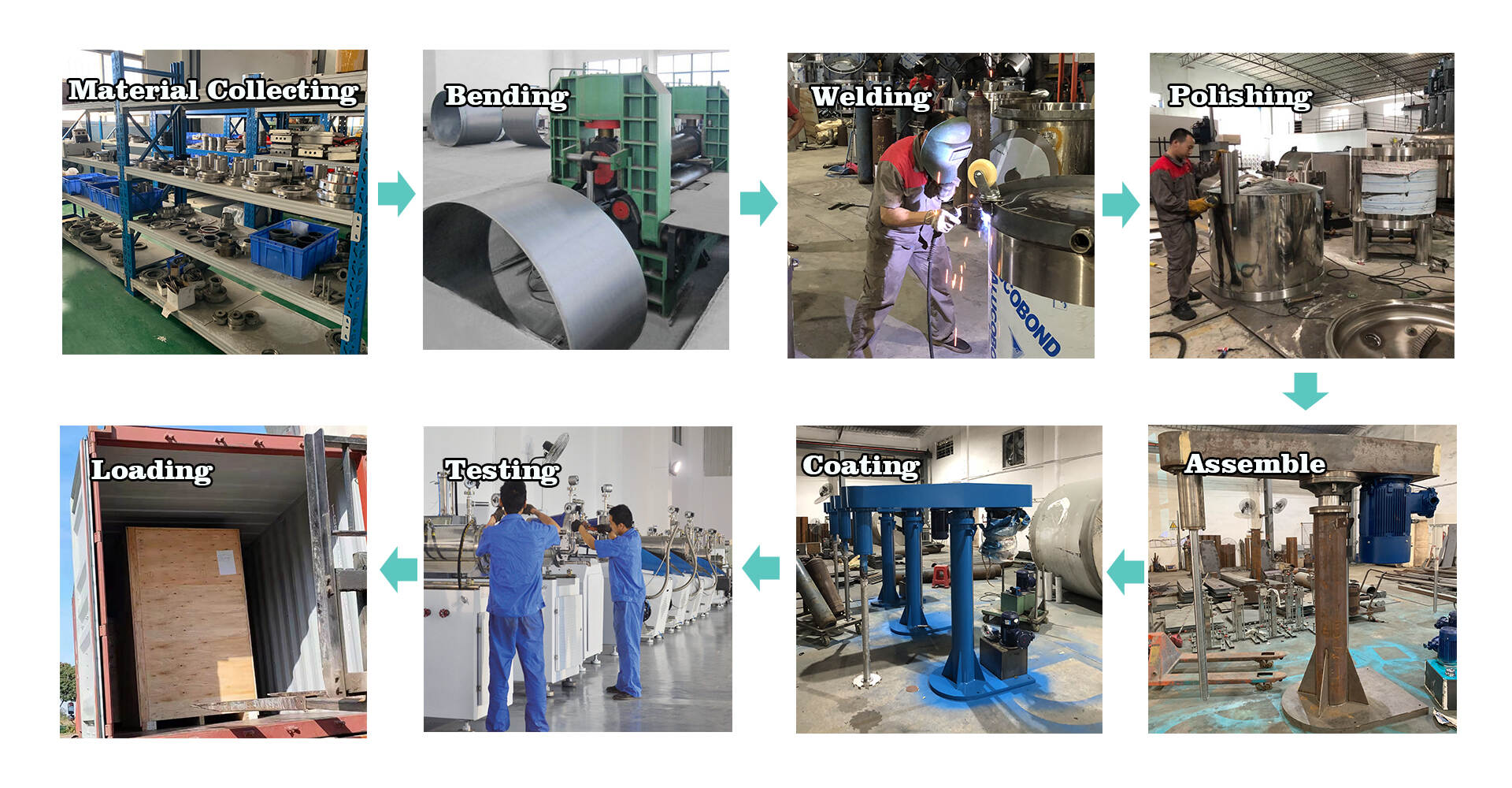

8. Manufacture Processing:

Our Chemical Machines are strictly quality control at every single production step, after quality past, we will move to do next step production.

Our Chemical Machines production process: raw materials preparing-cutting/bending materials-welding-polishing-assembling-coating-testing-packing-loading.

9. Packing And Shipping:

10. FAQ:

Question: Are you a factory or a trading company? where is your factory?

Answer: We are a real factory. Our factory is in fu'an industrial zone, leliu street, shunde ditrict, foshan city, guangdong province, China.

Question: Which countries your machine sold to?

Answer: American Market: America, Canada, Mexico, Brazil;

European Market: UK, Germany, Netherlands, Bulgaria, Italy, Russia;

African Market: South Africa, Algeria, Zambia, Cameroon, Ethiopia, Uganda, Madagascar;

Asian Market: Malaysia, Indonesia, Singapore, Vietnam, Thailand, Kazakhstan, Bangladesh, Pakistan, Lebanon, Iran, Iraq, Egypt, Qatar, Turkey, Saudi Arabia, UAE;

Question: How long is your machine warranty?

Answer: 12 months free for whole machine, After a year, spare parts charges, but life-long free for consultant.

Question: How long is your lead time?

Answer: Depends on the machines you choose. Generally from 7 days to 35days. Some big machine: 45-60days.

Question: How could I know how to operate the machines?

Answer: We provide teaching video and operating manual, and 24 hours in 7 days video guidance.

Question:How long is your machine warranty?

Answer: 12 months free for whole machine, After a year, spare parts charges, but life-long free for consultant.